Invisible doors for energy-efficient temperature separation

“Our ambition is to halve our CO2 emissions per euro of turnover by no less than 50% compared to 2010,” says Erik-Jan Termaten, Energy Project Manager at Sligro Food Group Nederland BV “Limiting our electricity and gas consumption plays a crucial role in this. We pay particular attention to this in both our existing and new locations. ”

As an example Termaten mentions the 25,280 m² large new building in Deventer, which has been designed and built according to the BREEAM-NL “Outstanding” certification criteria.

New product combination

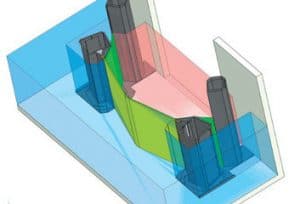

“Optimal separation is crucial, especially with deep-freeze cells,” says Deweerdt. “Not only to guarantee optimal temperature separation, but above all to prevent moisture entry and problems such as snow, fog and ice formation. After all, this can lead to significant energy and efficiency losses, high cleaning costs and even product or personal injury. With this in mind and in close collaboration with Sligro and the University of Ghent, we have carefully inventoried the conditions and processes in and around deep-freeze cells. This has led to the development of unique, slim, flexible and fully controllable Airstop and Powerstream setups, with which different temperature zones can be separated even more efficiently. The various product combinations were of course also applied in Sligro’s new distribution center in Deventer, where we had to deal with two types of partitioning: between the cooled (4 ° C) and non-cooled areas (20 ° C) and between the cooled areas and freezer cells (-24 ° C). ”

NewCold values the impact its partners have on its success and collaborates with TGW Logistics Group, SKT, B-Built, Ancra, Celonis, Fisher Construction Group, CGI, Kingspan, SSI Schaefer, Masterveil/De Weerdt BV and Subzero Constructors. This affirms why each of these partnerships are critical to driving success at NewCold.

NewCold values the impact its partners have on its success and collaborates with TGW Logistics Group, SKT, B-Built, Ancra, Celonis, Fisher Construction Group, CGI, Kingspan, SSI Schaefer, Masterveil/De Weerdt BV and Subzero Constructors. This affirms why each of these partnerships are critical to driving success at NewCold.

The thermographic images show a high pressure and a volume system in comparison.

The thermographic images show a high pressure and a volume system in comparison.

On May 20, HANOS opened its newest location on the Westermaat Campus business park in Hengelo.

On May 20, HANOS opened its newest location on the Westermaat Campus business park in Hengelo.

On May 20, HANOS opened its newest location on the Westermaat Campus business park in Hengelo.

On May 20, HANOS opened its newest location on the Westermaat Campus business park in Hengelo.