In the deep-freeze sector, the requirements for an air curtain system are far-reaching. This is not only about the delimitation of the two temperature ranges, but above all about minimizing the entry of humidity into the freezer area. The incoming humidity is visible without shielding by mist, snow and ice formation and leads to a hygiene vulnerability. Most air curtain systems in the freezer compartment condition their entire air jet with heat. This warmer air can absorb more moisture than the cold air in the freezer and thus transports the incoming humidity.

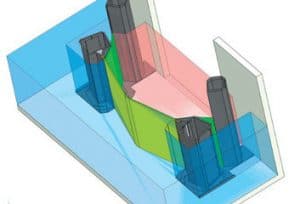

Another possibility is the use of a second air jet. Based on the principle of the high pressure system with a defined directed air jet, a second jet of air is generated. Only this one is conditioned. This so-called insulation air jet compensates for the humidity and in this way minimizes the entry of moisture into the freezer area.

Second air jet